TTK Project Case Study: TTK at Frankfurt Data Center Building, Germany

TTK WATER LEAK DETECTION SYSTEM AT A FRANKFURT DATA CENTER BUILDING

View the case study in PDF format.

Project Background

A plant room and a server room were equipped with a German brand analog water leak detection system installed over ten years ago – this out-of-date system is not equipped with any Modbus or TCP/IP interface allowing modern communication with BMS. Furthermore, frequent false alarms emitted by the system disturb the facility management’s daily operations.

The client decided to reinforce the security level in the critical areas by replacing the old analog system with a new, reliable digital system to benefit from the technical progression this modern system has.

TTK’s Solution

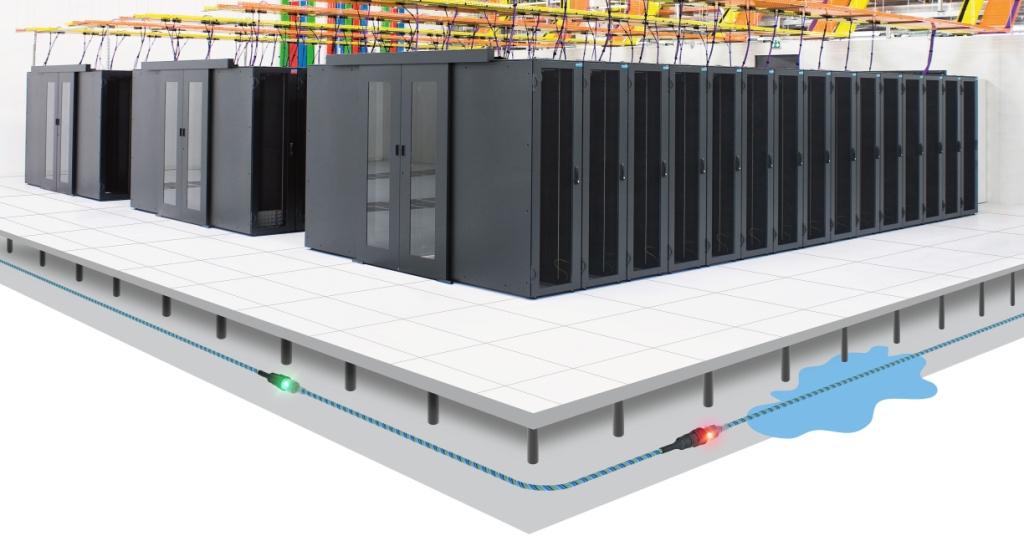

TTK Germany recommended its over-edge digital water leak detection system – the FG-NET panel with FG-EC addressable water sense cables - be installed under the false floor to the perimeter of both the plant room and server room.

Sense cables:

- Differing from the analog sensing cables, each length of FG-EC cable contains an embedded microprocessor which intelligently monitors the cable status and provides continuous real-time communication to the TTK digital units. Moreover, its highly visible LED (placed on the female end connector) provides quick identification of the cable status, which is extremely helpful for technicians working in the dark environment under the false floor:

- Green LED: normal status, no alarm raised

- Red LED: leak detected on the cable

- LED off: cable break on this or any upstream cable

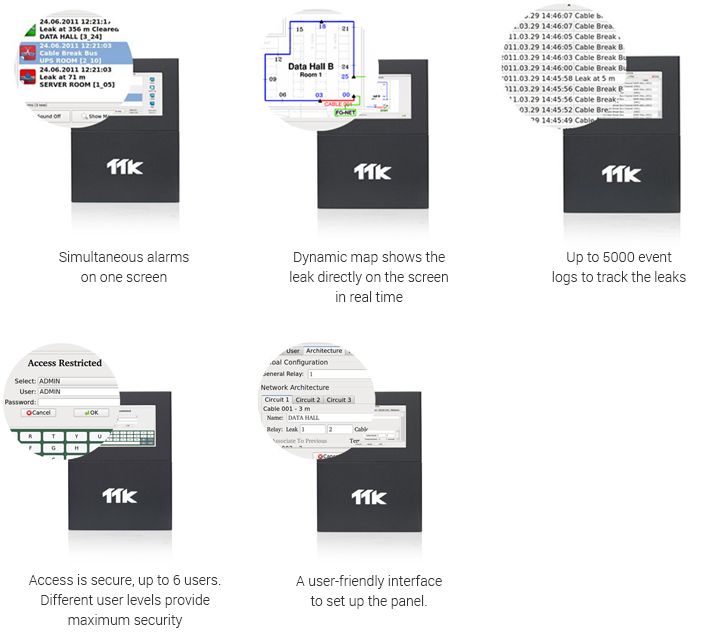

Digital monitoring panel:

- The FG-NET monitoring panel is integrated into the existing electrical control box inside the technical room on the ground floor. It is connected to the central building control system via Modbus communication protocol available on the panel.

- In the event of a leak, the FG-NET displays the leak location on its touch screen, precise to 1m. Furthermore, it drives dynamic drawings on the host BMS, which can be visualized at the same time on the central building control room’s screens.

- Up to 120 lengths sense cables (or 1800 metres) can be managed independently by the FG-NET panel. In the example of this case study, over 30 lengths of FG-EC water leak sense cables were installed on one single FG-NET panel, allowing for easy extension if required in the future. Both water sense cables and oil sense cables could be added to this same system to protect further areas from the risk of water or oil leaks.